Injection

Mould Making

We produce injection moulds for plastic, zinc,

aluminum die casting and car blow moulds.

What injection

moulds we produce

We’ve been producing injection moulds for plastics, zinc, aluminum die casting and car blow moulds for automotive and other industries for more than 10 years. We’re able to produce plastic moulds up to 25 tons. Contact us if you have any special requirement or need to supply a mould in a short time. We’re actively looking for possible solutions to help you and make you satisfied with our services.

Expert

know-how

We create 3D mould designs in-house. We’ll also provide you with full support in DFM and Mould-flow analysis.

Quality

steel

During moulds making we use standard suppliers of steels for shaped parts and mould frame.

Transport

in EU

We’ll arrange delivery anywhere in Europe for finished moulds.

Qualified

supervision

When manufacturing in China, we have a professional external supervision of quality of processing, including mould testing.

Designing

We design and construct the form for you in the 3D software program.

Prototyping

We prepare a single purpose tool in 3D software so you can try it in practice before you run the series.

Laser

welding

We carefully repair your crashed moulds. There is no internal stress on steel during welding.

Precision engineering

and machining

We work with an accuracy of 0.01 mm. Our experienced technicians work with NC machines, sinkers and wire cutters.

Production and

design of control

and measuring jigs

Inspection and measuring jigs make it easy to check your finished mouldings. We take care of design and production.

Custom made

copper or

graphite electrodes

We produce copper and graphite electrodes necessary for EDM (cavity sinking) machining.

Other services

In addition to producing, repairing and modifying injection moulds and making semi-automatic machines for the automotive, pharmaceutical and technical industries, we also offer other associated services.

Tooling equipment

For production and service of moulds we use besides

common machines such as lathes, round and flat grinding machines,

drills and milling machines as well professional machining centers.

1× CNC

Machining Centre

Fadal VMC 3016

maximum weight on table: 1 241 kg

maximum working range: X-760 | Y-406 | Z-600

1× CNC

Machining Centre

Fadal VMC 6030

maximum weight on table: 1 689 kg

maximum working range: X-1 524 | Y-762 | Z-762

1× CNC

Machining Centre

MAS MCV 1270

maximum weight on table: 1 200 kg

maximum working range: X-1270 | Y-610 | Z-720

1× CNC

Machining Centre

MAS MCV 754

maximum weight on table: 400 kg

maximum working range: X-754 | Y-500 | Z-500

2× EDM

Electro Erosion

Machining

1× Hole

Drilling

2× WEDM

Wire Cut

3× Welding

(Laser, Mikro-tig

& Tig)

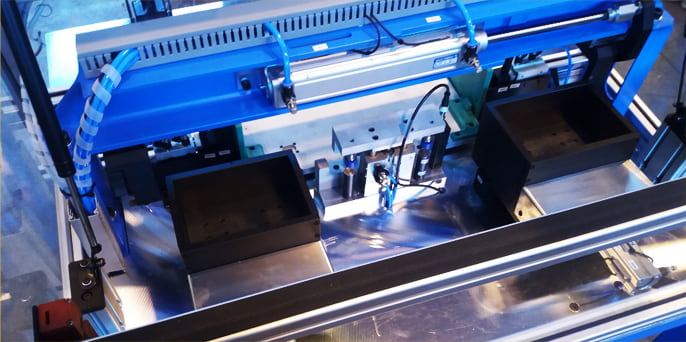

Semi-automatic Machines

We provide design, 3D construction and production of semi-automatic machines or measuring and control jigs. Learn more >